Description

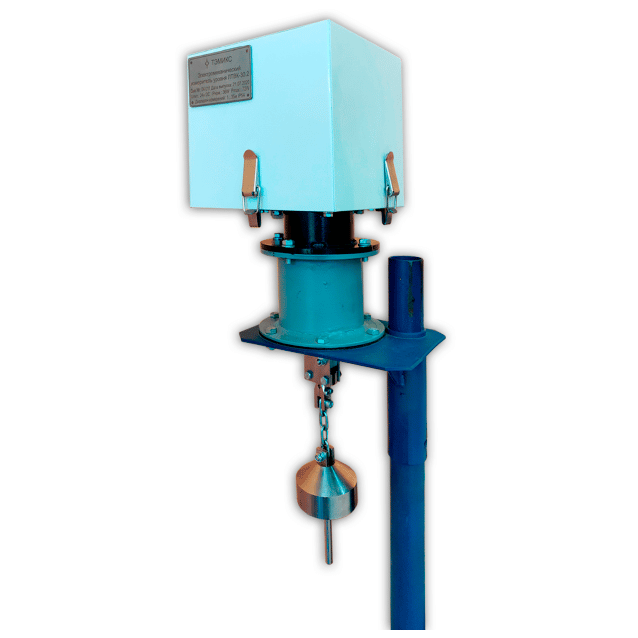

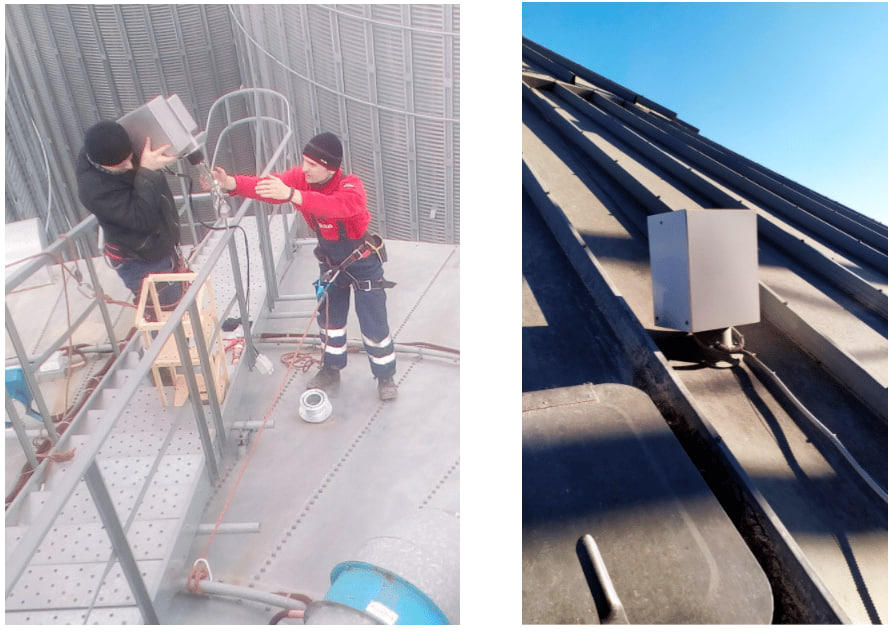

The electromechanical level gauge LTVK-30.2 is designed to measure the level of bulk products in silos up to 35 meters high. Measurement is carried out by lowering a load on a stainless steel belt until it touches the surface of the product, after which the gauge’s motor lifts the load back to its initial position. The LTVK-30.2 gauge is installed on the roof of the silo (tank) using a mounting flange, which ensures a tight connection and compensates for the roof’s angle.

The gauge’s body is made of steel, with an IP54 protection rating, and it includes a mechanism for cleaning the belt from dirt and dust. Installation of the gauge is possible both indoors and outdoors. The special shape of the load allows for measuring the level of almost any bulk materials (grain, meal, pellets, cement, building mixtures). Dustiness of the surrounding environment does not affect the accuracy of the measurements.

Installation of the LTVK-30.2 gauge is carried out in accordance with the passport for the LTVK-30.2 gauge. The installation process is straightforward and does not require specialized tools.

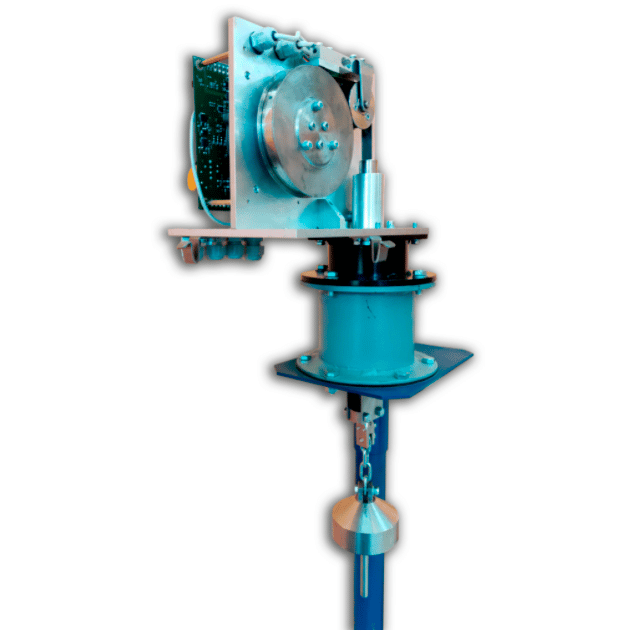

The LTVK-30.2 gauge is controlled by a built-in microcontroller and features self-diagnostic capabilities, as well as a set of sensors for measuring operating parameters and detecting abnormal situations.

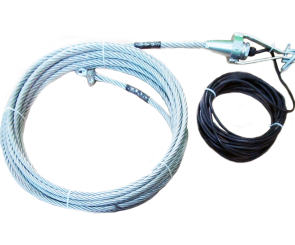

Figure 3. Components of the LTVK-30.2 gauge before assembly

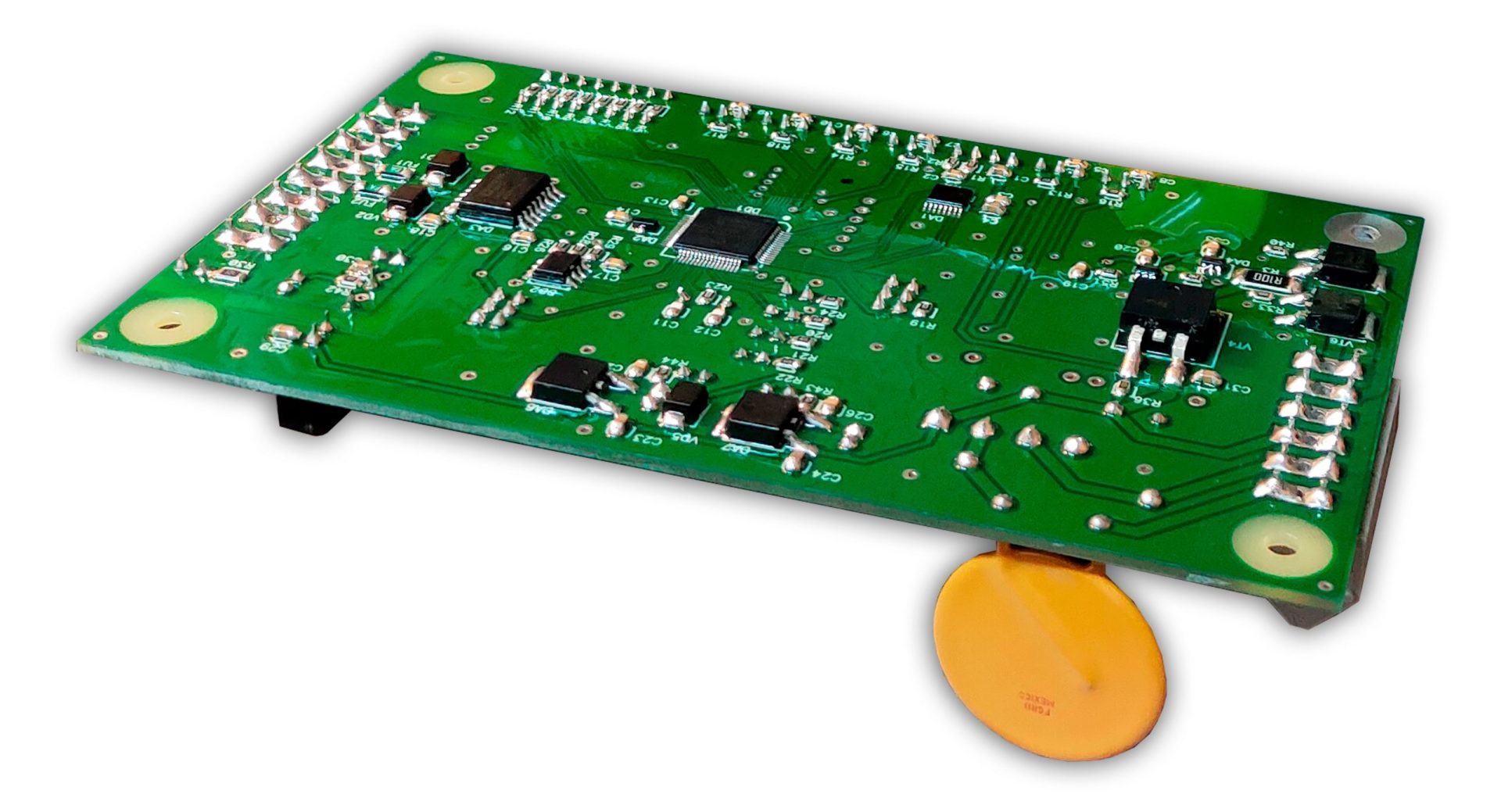

Figure 4. Controller of the LTVK-30.2 gauge

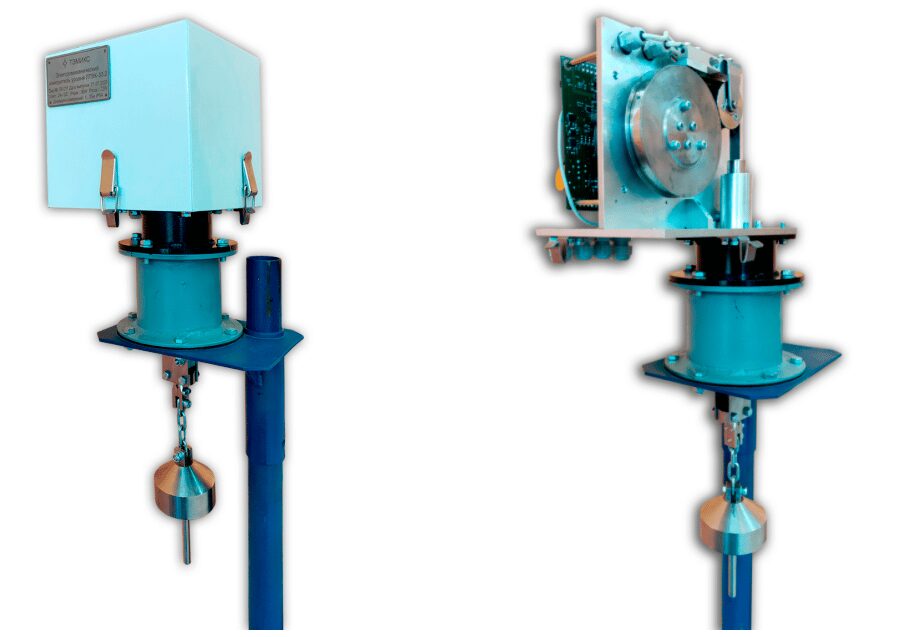

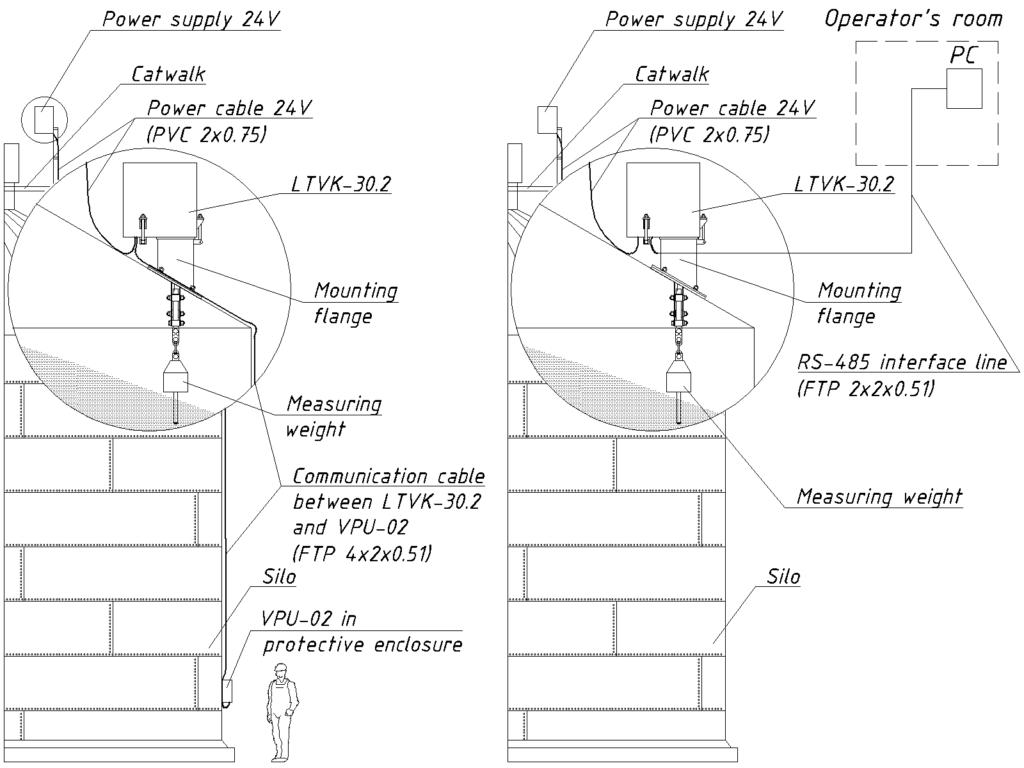

The electromechanical level gauge LTVK-30.2 is available in two application variants: autonomous (see Figure 5) and automated (see Figure 6).

1. Autonomous variant.

Supply kit:

1. Electromechanical level gauge LTVK-30.2.

2. Remote control and indication station VPU-02 with a protective enclosure.

3. Power source.

4. Mounting flange.

5. Passport for the electromechanical level gauge LTVK-30.2.

The VPU-02 station is equipped with an LCD display and buttons, which are used for indicating measurement results, controlling the operation of the LTVK-30.2 gauge, and its diagnostics.

The VPU-02 station is supplied in a protective metal enclosure and is installed in a convenient service location, typically at the bottom of the silo.

One VPU-02 station is designed to work with both a single gauge and a group of LTVK-30.2 gauges, up to 63 units. A group of gauges operated from one VPU-02 station is connected to a network according to the RS-485 standard, Modbus communication protocol.

2. Automated variant.

Supply kit:

1. Electromechanical level gauge LTVK-30.2.

2. Software “LTVK Level Gauge” (on a flash drive).

3. Interface converter and line protection unit (RS-485/USB) BPZ-4.

4. Power source.

5. Line protection module MZL-1.

6. Mounting flange.

7. Passport for the electromechanical level gauge LTVK-30.2.

Additionally, upon agreement with the Customer, connecting cables are supplied.

The operation of the gauge is controlled from a PC using the “LTVK Level Gauge” software. The “LTVK Level Gauge” software allows generating reports on the change of product level in the silo and saving them in the database, as well as diagnosing the condition of the LTVK-30.2 gauge. Level measurements can be performed according to a schedule set by the operator.

LTVK-30.2 gauges can be networked with control from a single PC (RS-485 interface, Modbus communication protocol), and can also be integrated into a higher-level SCADA system.

You can find more detailed technical information in the passport for the LTVK-30.2 level gauge.

You can download or view the passport at the following link: LTVK-30.2 Level Gauge Passport