The grain elevator thermometry system is a complex of hardware and software tools for monitoring the temperature of the grain mass during storage in silos, warehouses, and bunkers.

The main cause that reduces the quality of grain during storage in elevator silos is the process of self-heating of the grain mass. Timely detection of the process of grain self-heating at the initial stage not only leads to a decrease in its quality but also to a significant increase in the temperature of the grain (above 35°C) in the self-heating zone. In cases where the self-heating zone is not detected in time, the temperature continues to rise, leading to grain combustion, which ultimately can result in the destruction of the elevator silo structure.

The process of grain self-heating at the initial stage of its development is quite prolonged and characterized by a low rate of temperature increase. With an increase in temperature, the rate of temperature rise sharply increases, and consequently, the time allotted to take measures to prevent grain combustion decreases.

Temperature control of grain (in the elevator, silo, or warehouse) is the most effective and practical way to monitor the results of biochemical processes occurring in the grain mass during storage in grain storage facilities. Measuring the temperature in the grain mass (elevator, silo, or warehouse) allows us to judge its condition during storage.

TEMIX company offers the ITU-3 temperature control system (ITU-3 System) for grain storage of any type, providing reliable temperature control of the grain. The ITU-3 system is designed for installation in both new grain storage facilities and for the modernization (replacement) of thermometry systems such as DKTE-4MG, MARS-1500, M5, etc., previously installed in elevators. Modernization and repair of thermometry systems of any type and design. The ITU-3 system can be installed both in large elevators and small grain storage facilities.

Implementation of the Grain Temperature Control System ITU-3 (thermometry system) allows:

- Reducing losses from spoilage and drying of grain.

- Minimizing operational costs for grain storage.

The ITU-3 temperature control system is designed to work with temperature probes such as TP-1M used in many reinforced concrete elevators and floor storage warehouses, as well as with modern probes TP-DM, TP-DN, TP-DS, and TP-01M produced by LLC «TEMIX».

The ITU-3 system can simultaneously work with the TP-1M, TP-01M, and TP-DM probes. The grain temperature control system (elevator, silo, or warehouse thermometry system) can be built with ITU-3 equipment and probes from other manufacturers, made based on digital sensors (OPI INTEGRIS, etc.), copper-constantan thermocouples (SafeGrain, BOONE, etc.), as well as thermoresistors.

The ITU-3 system is made of modern materials and electronic components, which significantly increases its reliability and service life compared to relay systems.

- The system has been certified with the type approval certificate for measuring instruments No. UA-M1/1p-1669-2005.

- The system complies with TU U 33.3-13841758.007:2005 and is included in the State Register of Measuring Instruments of Ukraine.

The ITU-3 system is a set of modern technical tools designed to organize temperature control in silos, elevators, or warehouses. The elements of the ITU-3 system are developed to provide the capability to synthesize the temperature control system for grain storage of any type and size optimally.

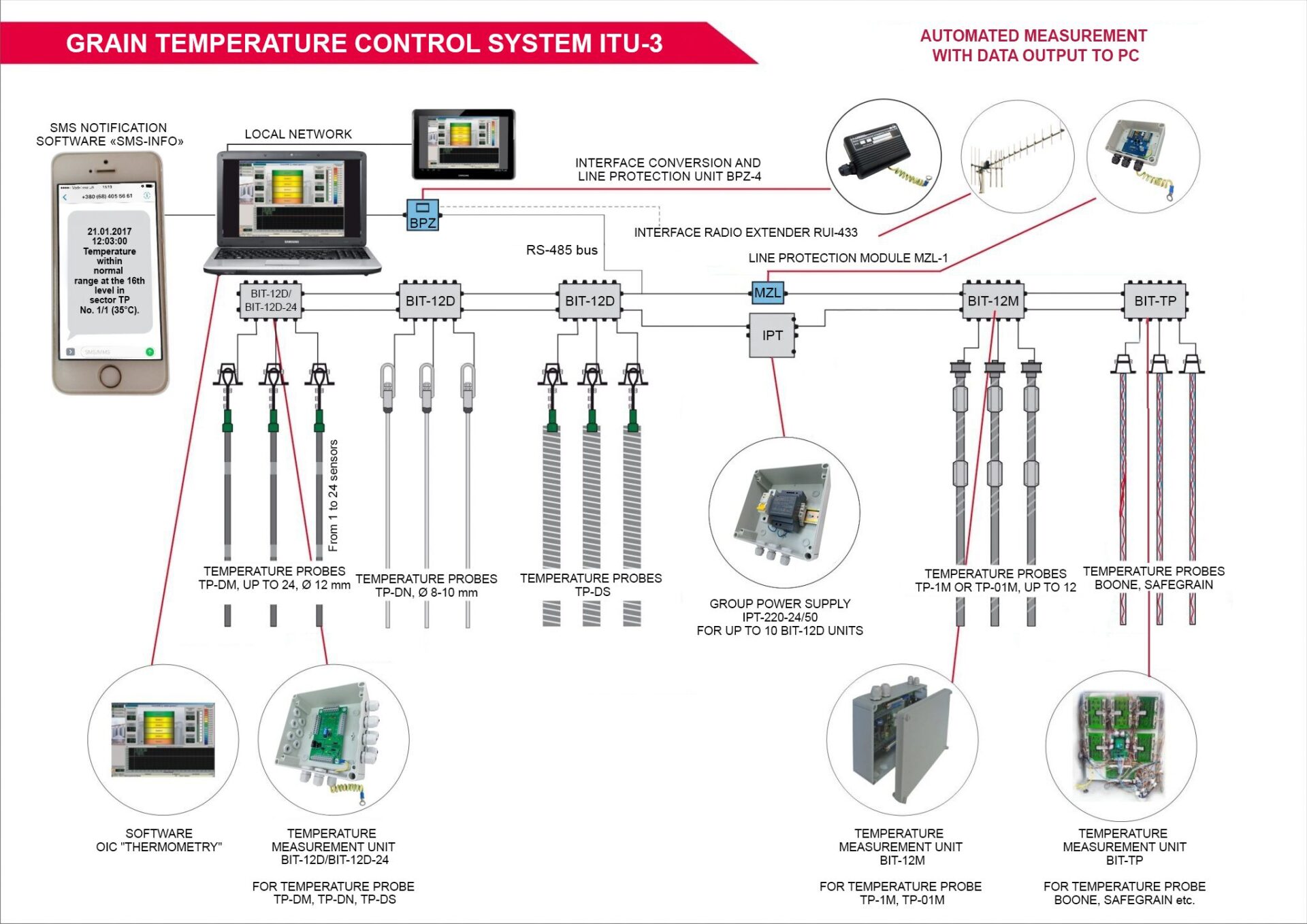

The structural diagram of the ITU-3 system is generally represented in the structural scheme (Fig. 1), and its specific implementation is determined by the chosen method of measurement (manual or automated), the number of grain silos, and the dimensions of the elevator (grain storage), as well as the type of temperature probes.

Fig. 1. Grain Temperature Control System ITU-3 (Structural Diagram)

Temperature measurement in the grain mass is carried out using temperature sensors placed in the cavity of the temperature probes. In manual measurement mode, temperature readings are displayed on the screen of the Temperature Indication Module (MIT-2), which works with TP-DM, TP-DN, or TP-DS probes, or on the Portable Measuring Device (PIP-1M), which works with TP-1M or TP-01M probes. MIT-2 and PIP-1M are connected directly to the temperature probe or, for TP-DM probes, through the power supply and switching unit (BPK-2 and BPK-2-24).

In automated measurement mode, temperature readings are displayed on a personal computer (PC) using Thermometry software. The temperatures measured by the temperature probes in digital form are transmitted to the PC via measurement units such as BIT-12D, BIT-12D-24, BIT-12M, or BIT-400TP.

Our products allow for the construction of new thermometry systems as well as the repair/modernization of already installed systems from brands such as StorMax, Rolfes, BOONE, SafeGrain, MyTemp, and OPI INTEGRIS.